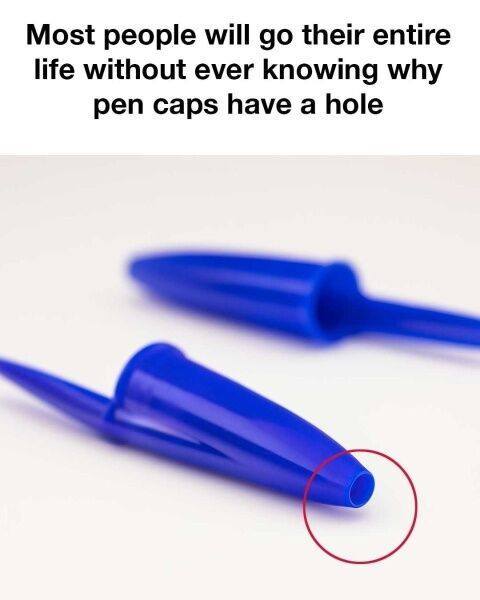

One of the most important reasons for that hole is safety. Small items like pen caps can be dangerous if they get accidentally swallowed, especially by children, as they can block the airway and cause choking. That little hole in the cap is designed to allow air to pass through even if the cap gets stuck in someone’s throat. This significantly reduces the risk of suffocation. This safety feature has become a standard in pen design, and it often follows guidelines set by safety organizations around the world to help prevent these kinds of accidents.

Reason 2: Making Sure the Ink Flows Smoothly Through Pressure Equalization:

Another really important reason for the hole is to help with pressure inside the pen. When you put the cap on a pen, or when the temperature or the altitude changes, the pressure inside the pen can also change. If there’s no way for the air pressure to equalize, it can cause problems like ink leaking out or the ink flow becoming inconsistent and unreliable. That little hole acts like a tiny vent, allowing air to move in and out of the pen. This prevents pressure from building up and helps ensure that your pen writes smoothly and consistently over time.

Reason 3: Helping with Manufacturing and Keeping Costs Down:

From the perspective of making these pen caps, adding a hole can also be a smart way to save money. The hole means that less plastic is needed to produce each cap, and when you’re making millions of them, those small savings in materials can really add up. Additionally, the hole can actually make the process of molding the plastic caps a bit simpler and faster, which also helps to keep the overall production costs down.

Reason 4: Adding to the Look and Design of the Pen:

Continued on next page