Measuring tapes are a staple in toolboxes around the world, used by professionals and DIY enthusiasts alike. Despite their ubiquity, many people misunderstand one of their key features: the loose tip. This seemingly faulty component often leads users to believe their tape is broken or defective. However, this design is intentional and serves a critical function. Understanding the purpose behind this feature can enhance the accuracy of measurements and improve the overall user experience.

The Common Misconception About the Loose Tip

When people first notice the loose tip of a measuring tape, they often assume it is a manufacturing defect. The tip, which appears to wobble or move slightly, can be mistaken for a sign of wear and tear. This misconception is widespread, as most users are not aware of the engineering behind this design. As a result, they may attempt to fix the ‘problem’ themselves, potentially compromising the tape’s functionality.

Understanding the Design of a Measuring Tape

The design of a measuring tape is a marvel of engineering, combining simplicity with functionality. The tape itself is made of a flexible metal strip that can be easily extended and retracted. The markings on the tape are precise, allowing for accurate measurements. The loose tip, often made of metal, is attached to the end of the tape. This tip is designed to move slightly, a feature that is crucial for ensuring accurate measurements whether the tape is used to measure inside or outside dimensions.

The Purpose Behind the Loose Tip

CONTINUE READING NEXT PAGE

How To Make Crack Chicken Pinwheels Recipe

Crafting Your Own Apple Vinegar at Home: A Simple Guide

Easy Homemade Mozzarella Cheese with Just Two Ingredients

Breathe Fresh: Simple Steps to Detoxify Your Lungs at Home

Why do restaurants and hotels often put ice in their toilets?

Scampis with Cajun Shrimp

Homemade toothpaste that whitens teeth, treats cavities and gum disease

If you drink cucumber water every morning, this is what happens to your body

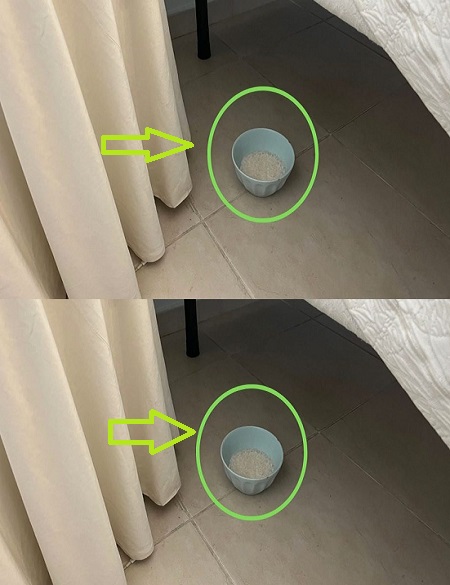

Using Salt Beneath the Bed